The Process of

Hydraulic

Fracturing

Hydraulic

Fracturing

The Process of

Hydraulic

Fracturing

Hydraulic

Fracturing

The Process of Hydraulic Fracturing

Talk with an Expert

Hydraulic fracturing produces fractures in the rock formation that stimulate the flow of natural gas or oil, increasing the volumes that can be recovered. Wells may be drilled vertically hundreds to thousands of feet below the land surface and may include horizontal or directional sections extending thousands of feet.

Fractures are created by pumping large quantities of fluids at high pressure down a wellbore and into the target rock formation. Hydraulic fracturing fluid commonly consists of water, proppant and chemical additives that open and enlarge fractures within the rock formation. These fractures can extend several hundred feet away from the wellbore. The proppants – sand, ceramic pellets or other small incompressible particles – hold open the newly created fractures.

Once the injection process is completed, the internal pressure of the rock formation causes fluid to return to the surface through the wellbore. This fluid is known as both “flowback” and “produced water” and may contain the injected chemicals plus naturally occurring materials such as brines, metals, radionuclides, and hydrocarbons. The flowback and produced water is typically stored on site in tanks or pits before treatment, disposal or recycling. In many cases, it is injected underground for disposal. In areas where that is not an option, it may be treated and reused or processed by a wastewater treatment facility and then discharged to surface water.

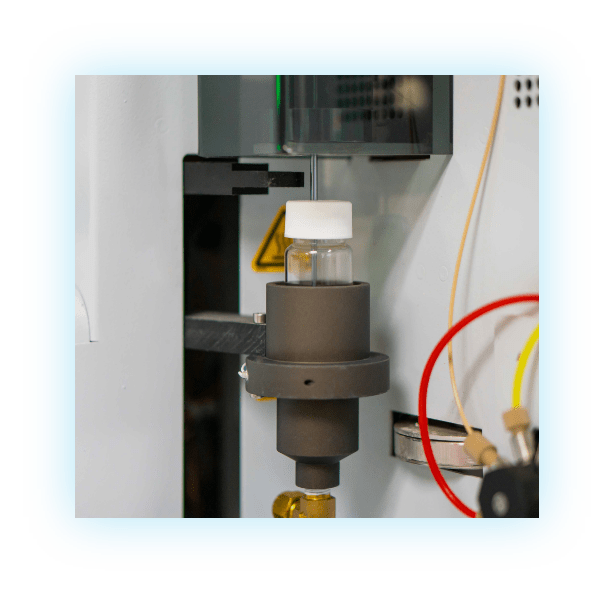

At A & B Labs, it is this flowback and produced water that is most often tested. Since there is much variation in the HF fluids used, the following packages are just a starting point.

Hydraulic Fracturing Parameters and Methods

| Test | Parameter | Method |

|---|---|---|

| Hydraulic Fracturing Basic | Total Dissolved Solids (TDS) Chloride Alkalinity Corrosivity (pH) Metals General Heterotropic Bacteria Dissolved Methane Ethane |

SM 2540C EPA 300.0 SM 2320B SM 4500-H+ B EPA 200.8 RSK-175 RSK-175 |

| Hydraulic Fracturing Package | Total Dissolved Solids (TDS) Chloride Alkalinity Conductivity Corrosivity (pH) Metals Dissolved Methane Ethane BTEX DRO GRO TPH Total Coliform Bacteria E. coli Bacteria General Heterotropic Bacteria Acid Producing Bacteria Sulfate Reducing Bacteria Heterotropic Plate Count Aerobic Plate Count |

SM 2540C EPA 300.0 SM 2320B SM 2510B SM 4500-H+ B EPA 200.8 RSK-175 RSK-175 EPA 602 EPA 8015D EPA 80125D TX 1005 |

Frequently Asked Questions (FAQs)

A & B Labs’ corporate office is located at 10100 East Freeway, Suite 100, Houston, Texas with service center locations in Harlingen (South TX), Euless (North TX), Nederland (TX Golden Triangle) and Baton Rouge, LA (coming soon). We serve clients throughout the United States based on our accreditations. Please view our Contact Us page for the full addresses of our service centers.

| Monday – Friday | 7:00 AM to 6:00 PM |

| Saturday | Closed (Please call 713-453-6060 if Saturday testing is needed.) |

| Sunday | Closed |

| After-hours / Emergency Testing | Please call 713-453-6060 if emergency testing is needed after normal business hours or during holidays |

Please contact your Project Manager at (713) 453-6060 or info@ablabs.com to schedule sample pick up and courier services in Houston and the surrounding areas, Bay City, Bloomington, Brazoria, Freeport, Ganado, Lake Jackson, Palacios, Port Lavaca, Port Comfort, Victoria, Wadsworth.

Sample pick up and courier services are also available in the areas near our service center locations in Harlingen and Corpus Christi (South TX), Euless (North TX), Nederland (TX Golden Triangle), Corpus Christi (South TX) and Baton Rouge, LA (coming soon). Additional locations may be available, please contact your Project Manager to learn more.

Our standard TAT is 7 business days or later for most tests. For test results needed in less than 7 business days, rush charges may apply. A & B Labs will provide the TAT on each quote.

Rush charges may apply to the tests, if needed and/or specified that the test must be rushed. Rush charges will only apply to those tests in which rushing the sample testing implies an actual cost. The rush

1 BUSINESS DAY TURNAROUND TIME = 100% SURCHARGE (When applicable)

2 BUSINESS DAY TURNAROUND TIME = 75% SURCHARGE (When applicable)

3 BUSINESS DAY TURNAROUND TIME = 50% SURCHARGE (When applicable)

4 BUSINESS DAY TURNAROUND TIME = 25% SURCHARGE (When applicable)

Sample matrix may affect feasible turnaround time

Note for Asbestos: A prep charge fee will be incurred if the samples are prepped but not able to be analyzed due to step rules for overloading. Bulk PLM that requires a separate report and analysis for individual layers will be charged accordingly, per layer.

A & B Labs will pay for the outgoing sample kit shipment costs if the kit order is received 5 business days in advance by using the most cost effective means of shipping available (Examples: UPS Ground Service, FedEx Ground, FedEx Express 3 Day, etc…). For International shipping, the client is responsible for shipping costs both outbound and inbound.

A & B Labs can provide sample media (at cost with a surcharge) provided the laboratory is given at least 5 days notice. Routine kits include PVC filters, MCE filters, sorbent tubes, chain of custody forms and Federal Express return shipment forms with A & B Labs’ ID number. Other media, pumps and related equipment are available for additional charges. All sample media will be charged to the client immediately after the media kit is ordered or given to the client.